Department Overview

The Mechanical Engineering branch was started in the academic year 2011-2012. All the laboratories have been established with full-fledged and state-of-art equipment facilities. The Department has a team of well-qualified members of staff, with a blend of industrial and academic experience. The Faculty Members with Master’s and Doctorate degrees, having specialization in machine design, thermal engineering, product design, and maintenance engineering are involved in academic and research activities.

The Department is committed to providing the students, technical expertise in theoretical, computational, and practical methods to analyse, solve, and meet challenges in ‘Mechanical Engineering Field’. Towards achieving this goal, the Department is fully equipped with the required facilities for effective delivery of lectures, full-fledged computational and laboratory facilities. A committed team and experienced well-qualified teaching and well trained supporting staff are involved in the delivery of theory and laboratory classes.

Apart from classroom teaching, students are encouraged to carry out simple projects to get hands-on training on what they learn in theory subjects. Industrial visits and guest lectures by experts of repute from industries/academia are arranged on a regular basis, to enhance learning and expose the students to the latest happenings in the field of Mechanical engineering.

BNMIT

To be a premier department for education in Mechanical engineering in the state of Karnataka, that moulds students into professional engineers.

- To provide a teaching-learning process that prepares engineers to meet the needs of industry and higher learning.

- Provide environment for self learning to meet the challenges of changing technology and inculcate team spirit and leadership qualities to succeed in professional career.

- To instill professional ethics and concern for environment for the benefit of society.

Department Overview

The Mechanical Engineering branch was started in the academic year 2011-2012. All the laboratories have been established with full-fledged and state-of-art equipment facilities. The Department has a team of well-qualified members of staff, with a blend of industrial and academic experience. The Faculty Members with Master’s and Doctorate degrees, having specialization in machine design, thermal engineering, product design, and maintenance engineering are involved in academic and research activities.

The Department is committed to providing the students, technical expertise in theoretical, computational, and practical methods to analyse, solve, and meet challenges in ‘Mechanical Engineering Field’. Towards achieving this goal, the Department is fully equipped with the required facilities for effective delivery of lectures, full-fledged computational and laboratory facilities. A committed team and experienced well-qualified teaching and well trained supporting staff are involved in the delivery of theory and laboratory classes.

Apart from classroom teaching, students are encouraged to carry out simple projects to get hands-on training on what they learn in theory subjects. Industrial visits and guest lectures by experts of repute from industries/academia are arranged on a regular basis, to enhance learning and expose the students to the latest happenings in the field of Mechanical engineering.

VISION

To be a premier department for education in Mechanical engineering in the state of Karnataka, that moulds students into professional engineers.

VISION

- To provide a teaching-learning process that prepares engineers to meet the needs of industry and higher learning.

- Provide environment for self learning to meet the challenges of changing technology and inculcate team spirit and leadership qualities to succeed in professional career.

- To instill professional ethics and concern for environment for the benefit of society.

Key Highlights

NBA has accredited the Department for the academic years 2018-19 to 2020-22 and valid up to 30.06.2025 and NAAC with A grade. The Institution has been recognized as Band Performer under ARIIA All India Ranking (2021-22).

Students has achieved 2nd rank, 10th rank in university level and 2 gold medals

Well experienced and highly qualified Faculty. 4 of the faculty are Ph.D. holders and the rest of them are pursuing Ph.D.

Ultra Model Center of Excellence by Toyota Kirloskar Motors Ltd. The Department maintains good collaboration between the industry and has signed MoU’s with various companies.

Key Highlights

01

The Department has been accreditedby NBA for the academic years 2018-19 to 2020-21 and NAAC with A grade. AIIRA ranking for Innovation and research by the Ministry of Education, New Delhi.

02

Students has achieved 10th rank in university level and 2 gold medals

03

Well experienced and highly qualified Faculty. 5 of the faculty are Ph.D. holders and the rest of them are pursuing Ph.D.

04

Ultra Model Center of Excellence by Toyota Kirloskar Motors Ltd. The Department maintains good collaboration between the industry and has signed MoU’s with various companies.

Dr. B S Anil Kumar

Professor and Head, Department of ME

Message From The HOD

As the Program Head, I, Dr. B.S. Anil Kumar, extend a warm welcome to the prestigious Mechanical Engineering Department at B.N.M. Institute of Technology, Bangalore.

Our department was established in 2011 with a vision of empowering the future Engineers/Innovators to revolutionize the world through excellence in Mechanical Engineering education with a focus on research, innovation & readiness for industry.

The department is fully pledged to deliver the best-in-class learning in the 3 major building blocks of the Mechanical Engineering field – Design, Thermal Sciences, & Manufacturing. We are committed to providing our students with technical expertise in theoretical, computational, and practical methods to analyze, solve, and meet future challenges in all the relevant areas of Mechanical Engineering. To accomplish this objective, our department is equipped with state-of-the-art facilities for efficient course delivery. Our syllabus is redefined to meet modern industrial and research standards, with advanced curricula incorporating AIML and Software-related disciplines as recommended by industry experts. In addition to classroom teaching, we also encourage students to carry out real-time projects to bridge the gap between theoretical knowledge and its application. In addition to this, we also conduct regular industrial visits and invite Subject-Matter Experts from industry and academia to deliver guest lectures to enhance learning and expose our students to the latest trends & advances in Mechanical Engineering.

A few distinguished features of our department include:

• BNMIT-Toyota Centre of Excellence.

• Centre of Excellence in 3D Printing Technology.

• An array of MoUs with reputed industrial partners.

• Outstanding faculty with a blend of excellent academic records, extensive teaching experience, and industrial exposure.

• Dedicated counselor for each student to ensure individual attention.

• Excellent infrastructure and well-equipped hardware & software laboratories.

• DST/KSCST funded projects are carried out by the students in a regular basis

Dear students, our department is regarded as a “Temple of learning” and I am fully confident that you will acquire all the required technical, professional, and personal skills required to compete with students from around the world. I wish you all the best and a great start to this new and exciting journey of yours.

Mechanical Quiz

December 4, 2020

One day Student Workshop on “Aircraft and Aerospace Engineering”

November 14, 2020

Webinar on “Career Paths In Mechanical Engineering”

November 12, 2020

TESTIMONIALS

- Alumni

- Student

- Parent

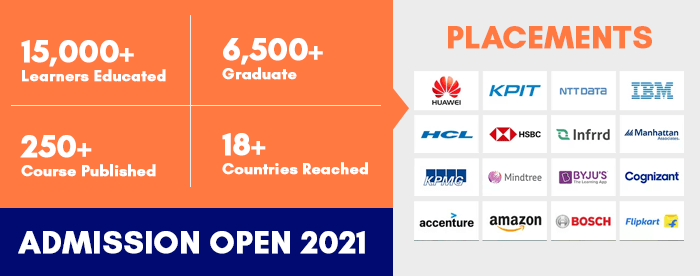

ACCREDITATIONS

BNMIT has been accredited with ‘A’ Grade by NAAC. All UG branches – CSE, ECE, EEE, ISE & Mech.E accredited by NBA for academic years 2018-19 to 2024-25 & valid up to 30.06.2025