The department is fully equipped with the required facilities for the effective delivery of lectures, state of the art computational facilities, and laboratory facilities. More emphasis is being given to practical classes through effective, elaborate, and rigorous laboratory classes to reinforce the theoretical knowledge gained during theory classes. At present, the following laboratories have been established in the department.

Engineering Graphics Laboratory

This subject focuses on the fundamentals of engineering graphics and technology. Since drawing is the language of communication for engineers and has applications in all branches of engineering, students of all branches have to undergo this course. In order to expose students to current industrial practices, students are trained on CAD software Solid Edge ST 6 to practice 2D drafting. The lab is well equipped with 48 high-end computer systems for the students to practice and LCD projector facilities for the delivery of lectures.

Computer-Aided Machine Drawing Laboratory (CAMD Lab)

Design drawings allow viewers to visualize a machine or its components before it is manufactured. In the current industrial trend CAD modeling is an imperative skill expected from all Mechanical engineers. Students practice the development of 3D drawings of machine components and perform virtual assembly using industry leading mechanical design software Solid Edge ST 6. Solid Edge modelling and assembly tools enable students to easily develop a full range of products, from single parts to assemblies containing thousands of components with accurate fit and modify them within the assembly model. The lab is equipped with 40 numbers of high end computer systems.

Material Testing and Metallography Laboratory (MMT Lab)

Engineers in general and Mechanical engineers in particular should have knowledge of properties of engineering materials and their applications. Different materials have different physical, chemical and mechanical properties and suitability. Testing the material for its mechanical strength forms an integral part of manufacturing. In this lab the students are exposed to the procedure of testing of engineering materials with help of Universal testing machine, various hardness testing machines (Rockwell, Brinell, Vicker’s) , Wear , Impact and Torsion testing machines along with optical microscope required for metallographic examination of materials.

Foundry, Forging and Welding Laboratory

In foundry, the students are guided in preparing the mould cavities using foundry sand. This section also has the facilities to test the moulding sand properties like grain fineness test, moisture content test, mould hardness, core hardness test, etc. using well-equipped instruments. The Foundry & Forging laboratory being smoke-free (unique of its kind) is furnished with setup’s of LPG fired furnace for performing forging models and is also equipped with foundry sand testing apparatus with proper ventilation, space, and sufficient lighting.

Workshop and Machine Shop Practice

The Machine Shop is equipped with Centre Lathes, Drilling Machines, Shaping Machines and Milling Machine for preparing the models and gaining the practical exposure in operating the machines. Also, the machine shop is equipped with high quality cutting tools for the operations like Marking, Centre drilling, Facing, Taper turning, Grooving, knurling, Profile turning, Drilling, Boring, Thread cutting etc., The students are also trained in using inserts for cutting tool for machining purpose and Gear cutting operation.

Mechanical Measurements and Metrology Laboratory (MMM Lab)

An engineer must possess adequate knowledge of measurement techniques. Metrology and measurements constitute an important element in all laboratories for conducting experiments and for all types of control processes in the industrial activities. This lab provides the students an active learning environment for the measurement technologies used in production engineering field. Students use the laboratory to collect and analyze measurement data, evaluate measurement methodologies, and learn the capabilities and limitations of measurement technologies. The lab includes LVDT, Load Cell, Pressure transducer, Micrometer, Thermocouple, Slip gauges, Sine bar, Sine center, Bevel protractor, Profile projector, Lathe and Drill tool dynamometer and other equipments required for calibration and measurements

Fluid Mechanics and Machines Laboratory

Fluid mechanics is the study of fluids (liquids and gases) and forces on them. The fundamental purpose of the lab is the study of the phenomena and effects of flow of fluids by experimental measurements and computations while providing knowledge about the various types of turbines, pumps and blowers. The lab deals with the concepts related to natural flows, gas-thermodynamics, combustion, and flow and transport phenomena. The experiments related to the following topics are conducted in the lab: flow through pipes, impact on vanes, calibrations, turbines, nozzles, pumps and blowers.

Modeling and Analysis Laboratory (FEA)

Engineering analysis is part of Engineering Design process which takes preliminary design as input and gives final design as output. In order to carry out engineering analysis, it is required to develop mathematical model of physical phenomenon. Advancement in computers and software with suitable mathematical models and numerical methods has made it possible to solve practical problems of every engineering domain. Among the numerical methods, the Finite Element Method and its generalizations are the most powerful computer methods devised to analyze practical engineering problems. In modeling and analysis lab the students are trained to carry out engineering analysis in the area of Stress Analysis, Thermal analysis and Dynamic analysis using commercial FE software ANSYS. The lab is equipped with high end computers and ANSYS 15.0 version (Academic version and Advanced Research Version) of FE software.

Heat Transfer Laboratory

Heat and mass transfer explains the thermal energy interaction processes between physical systems. The heat and mass transfer lab is well equipped with the set-ups for the experiments on: natural convection, forced convection, radiation, emissivity, heat exchangers, refrigeration, air conditioning and unsteady state heat transfer. These experiments shall pave the way for the students to understand and appreciate the basic concepts of heat and mass transfer by providing in-depth practical exposure. Also the students shall be able to develop basic skill-sets in order to take up higher level experimental studies in heat and mass transfer in future.

Design Laboratory

Mechanical Engineering being the broadest and most diverse of all engineering domains aims at transforming ideas into products. During the course, the design of machine components, nano to giga is particularly a crucial job that demands careful attention from the domain experts.

The Design lab in the department of Mechanical Engineering at BNMIT aims at providing a platform for the students to implement the previously assimilated concepts in understanding the practical aspects of design related experiments. The facilities of the lab are so diverse that it gives them the opportunity to fortify their knowledge on stresses & strains, kinematics, dynamics, fluids, vibrations, etc. in a practical manner.

Further, the state of the art experimental setups with well qualified & experienced faculty provide a platform for the students to conduct research, carry out projects & validate their numerical simulations thus forming a corner stone in preparing the students for dynamic career opportunities.

CIM (Computer Integrated Manufacturing) and Automation Laboratory

CIM and Automation Laboratory, provides a high quality laboratory experience to students about manufacturing automation, advanced material processing, computer assisted and computer controlled manufacturing. The lab is equipped with high end computers and CADEM software viz. CNC TECHNOLOGY multimedia NCyclopedia software (NCyclo), CNC Milling and Turning SIMULATION software (seeNC) and CNC Milling and Turning CAM software (CAPS). The laboratory has latest CNC machines, XL TURN CNC Lathe Machine and XL MILL CNC Milling Machine to impart hands on training to students in the area of computer assisted and computer controlled manufacturing.

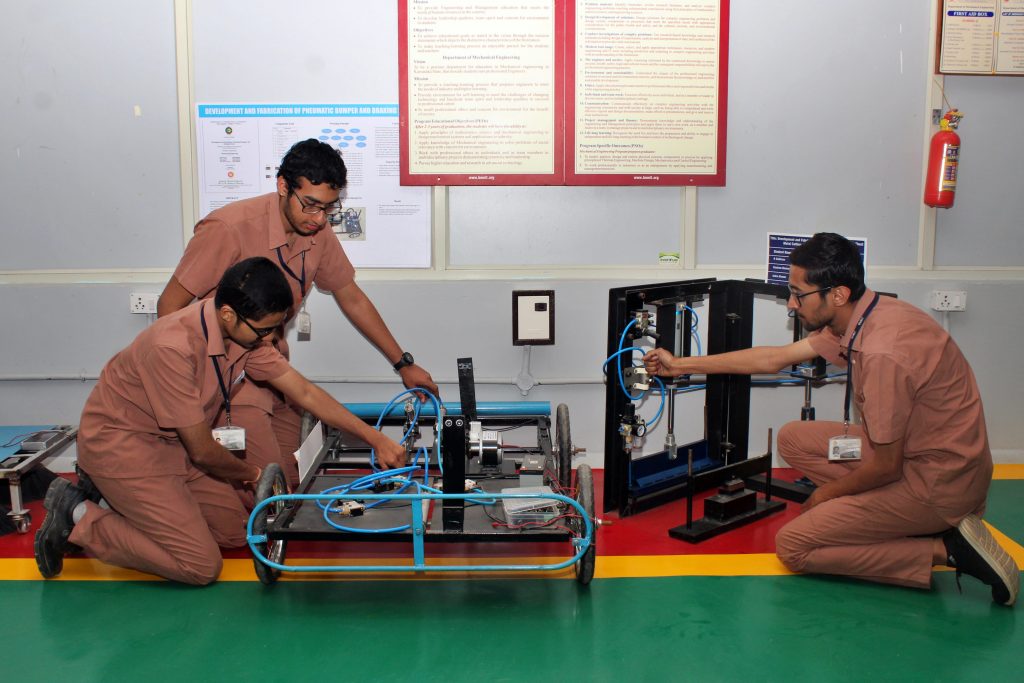

Project Laboratory

The Project Laboratory offers the students, the opportunity to work hands-on using facilities/ equipment’s/Technical help to carry out their projects right from first to eight semesters. The lab is equipped with fabrication as well as computational facilities, to support the students in their endeavor

BNMIT-Toyota Centre of Excellence

BNM Institute of Technology has associated with Toyota Kirloskar Motor Pvt. Ltd. to develop center of excellence. Here the students are trained in assembling and dismantling the parts of Toyota Innova four stroke diesel engine along with transmission system. Students are also exposed to gain the practical knowledge about the working principle of engine, gear engagement and transmission system through the cut section assembly of four stroke engine with transmission system. The centre of excellence is also having the working cut section of Toyota fortuner 4WD automatic engine and transmission with fully loaded chassis. The BNMIT-Toyota center of excellence provides opportunities for students to understand the needs of industry by analyzing the design and manufacturing methods of engine components.

Major equipments / components in the BNMIT-Toyota Centre of Excellence

- Four stroke diesel engines with gear box and transmission system (for assembling and dismantling)

- Cut section of four stroke diesel engine (INNOVA) with gear box and transmission system along with the differential. (for demonstration)

- Cut section of four stroke diesel engine (FORTUNER 4WD) with gear box and automatic transmission system, complete chassis, suspension, braking system along with the differential. (for demonstration)

Purpose:

- The BNMIT-Toyota center of excellence provides opportunities for students to understand the needs of industry by analyzing the design and manufacturing methods of engine components

Virtual Lab

Virtual Lab is an innovative program that lets you interact with a Laboratory experiments discovering its principles using ICT. Three Virtual Labs shall be added in the first phase. The virtual lab accessibility requires internet connectivity for remote access.

Objectives of Virtual lab

- The idea of virtual laboratory is to provide students with a platform to learn the experiments, procedure, sample calculations and video demonstration through visual aids without having the equipment at their end.

- The virtual lab program aims to provide the quality of learning in laboratory as a self learning exercise.

- It shall strengthen the understanding, self evaluation of fundamentals and accessibility to lab contents.