Six Sigma Green Belt Certification from MSME

SIX SIGMA GREENBELT

SIX SIGMA GREENBELT PROGRAMS is a 24 hours training program conducted by MSME (Ministry of Micro, Small and Medium Enterprise) in our college for the department of MBA students. 35 students with 3 faculty participated in the program. The duration of course was 12 days from 03/05/2020. The program was conducted through online (ZOOM) due to the pandemic situation.

Six Sigma Green Belt certification establishes professionals’ skills on data-driven approach and methodology for eliminating defects in any process across industries. It is set of tools and techniques for process improvement. It seeks to improve the quality of the output of a process by identifying and removing the causes, defects and minimizing impact variability in manufacturing and business process. It uses set of statistical methods/tools like Analysis of variance, Regression analysis, Correlation, Scatter diagram, Control charts, etc. here six sigma defines two concepts LEAN & SIX SIGMA. Six sigma reduces the variation in standards andactual, so when the variation reduces then the standards can be reached easily. Variation occurs from special and common causes. Lean helps to reduce the waste like over production, excess inventory, over processing, etc. so LEAN SIX SIGMA helps in reducing the waste and improving the quality so that the standards are met in time. A major target of quality assurance is the minimization of error rates in order enhance patient safety. It is a method targeting zero error (3.4 errors per million events) used in industry.

APPROACH OF SIX SIGMA: –

SIX SIGMA can be approached with five different phases where the problems are identified, measured, analysed, solutions can be improved and finally controlling the process seeing that whether the process is within the control or not.

- Define phase defines the project / an item / area in which there is a need for improvement. from the voice of customers, the problems are identified. VOC refers to the feedback, complaints, etc. there could be internal and external voices.

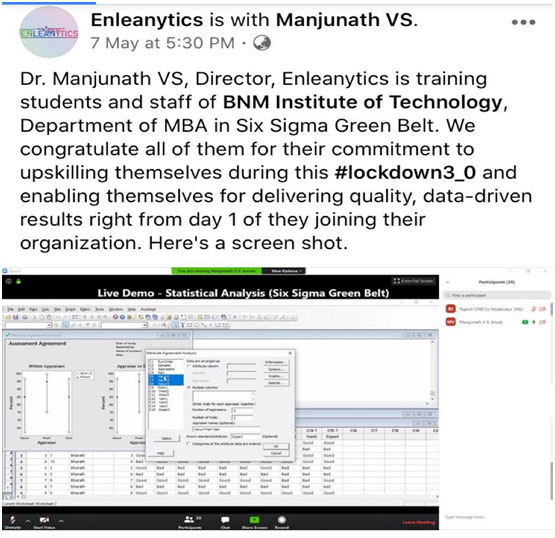

- Measure phase minimizes the measurement variation. Need for identifying how much variability / tolerance can be accepted. Repeatability and Reproducibility can be analysed. Kappa measures the attribute agreement.

- Analysis phase helps to identify the root causes and helps in focusing on the causes which have the greatest impact. Here tools used are paired sample T test, scatter diagram, pareto diagram, etc.

- Improve phase helps in improving the ideas. Solutions to the problems. Brain storming Activity.

- Control phase helps to keep improvement. Train employees to adapt new methods.

Outcome

SIX SIGMA can be used in any field like HR, MARKETING, FINANCE, etc. can be used in any kind of industry like primary, secondary/manufacturing, service industry. Six sigma benefits in professional development, analyse the business performance ahead of competitors, helps in discovering the main drivers of the problem.

This program adds the value as it is the greatest challenge for every company/industry, so certification of green belt will help facing the challenges. The concepts were very well explained through more number of examples. the process of using six sigma software (Minitab) was very well explained and the trainer was more student friendly, students were free to arise the questions and doubts were clearly solved. The tremendous effort of Teachers, Trainer and Students gave the successful end of the program.